AURORA SEIKI

Aurora Seiki Machining Centers and Turning Centers

Aurora Seiki is located in the heart of Taiwan’s heavy industry Taichung, providing advanced metalworking solutions and comprehensive services for production machining.

Aurora Seiki designs, manufactures, sells and supports CNC machine tools including Horizontal Machining Centers, Vertical Machining Centers, and CNC Turning Centers.

Aurora Seiki continues to pursue perfection and insists on following a healthy management philosophy in manufacturing machine tools. With their leading R&D team, they have created a division in developing and manufacturing machining centers known as Aurora Seiki Machinery.

Aurora Seiki believes in combining corporate resources and focusing on machine tools to provide a total solution to our global partners and valued customers with exceptional technology and quality.

F Series Vertical Machining Centers

- Exceptional Rigidity – Highly Rigid Structural Frame Design

- Highly Productive – High Performing, Powerful Machining Center

- Decidedly Efficient – FANUC Advanced CNC Controllers

- Remarkably Cost Effective – Safe & Convenient

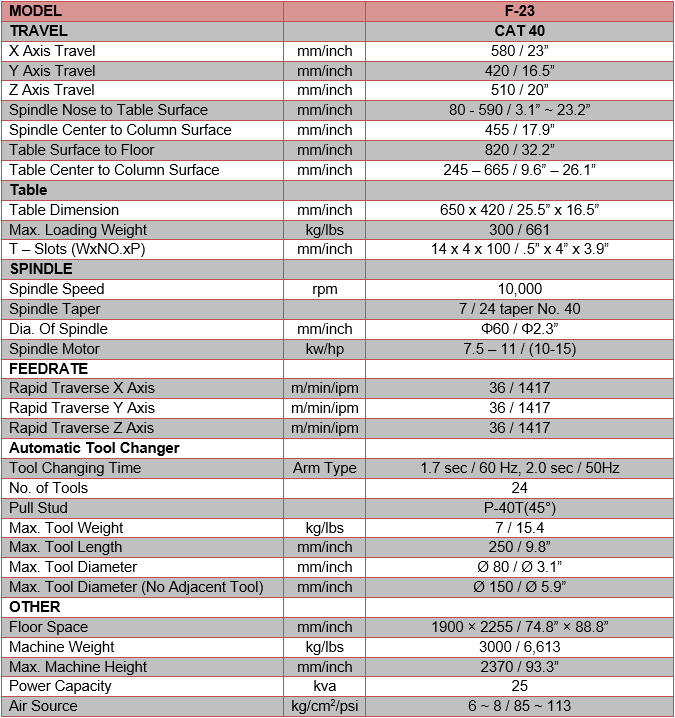

F-23

Standard Accessories:

|

|

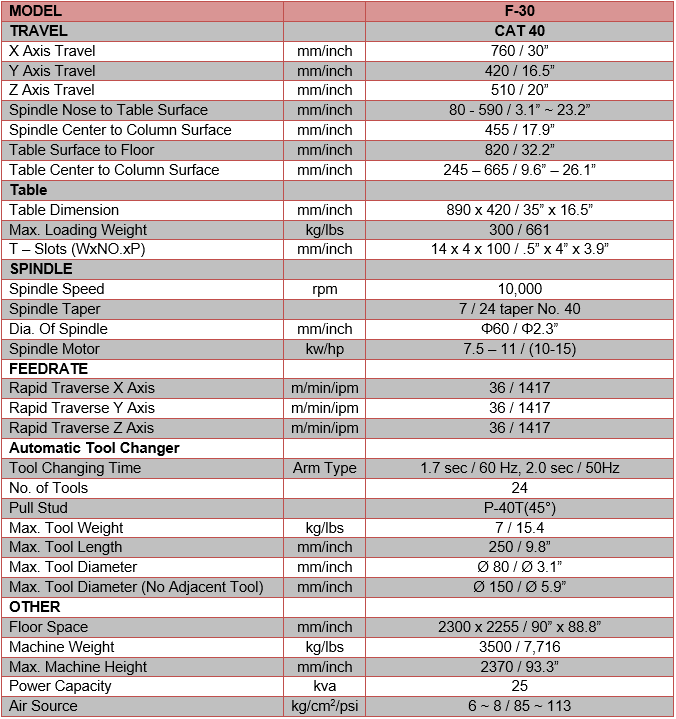

F-30

Standard Accessories:

|

|

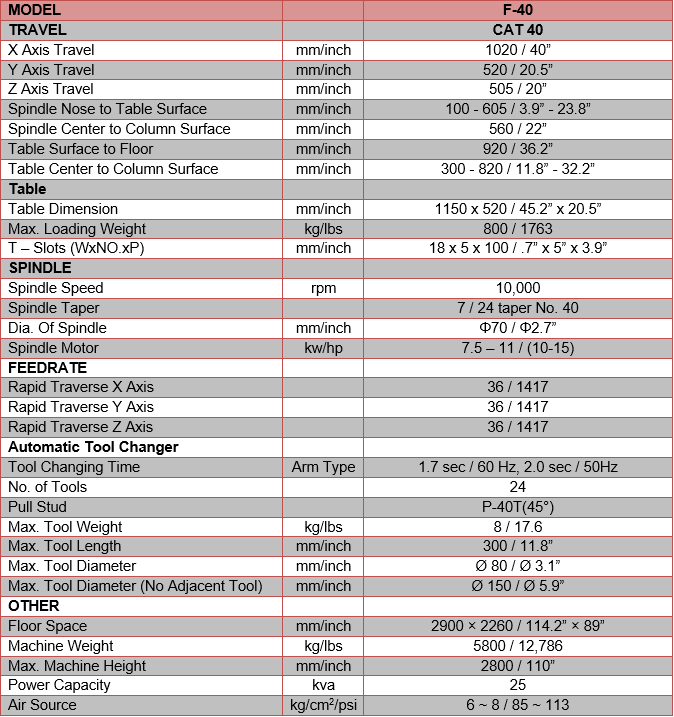

F-40

Standard Accessories:

|

|

F-53

Standard Accessories:

|

|

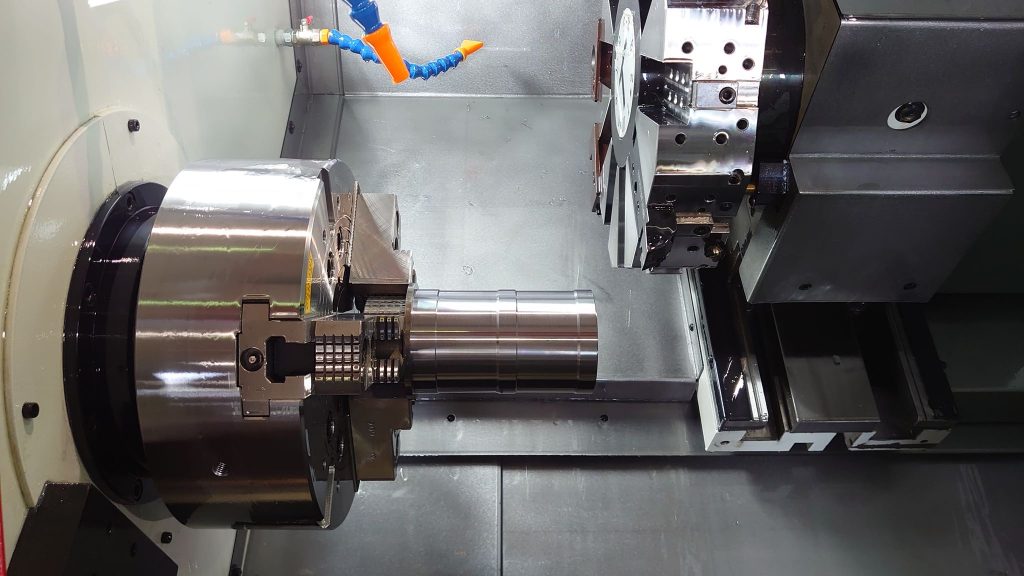

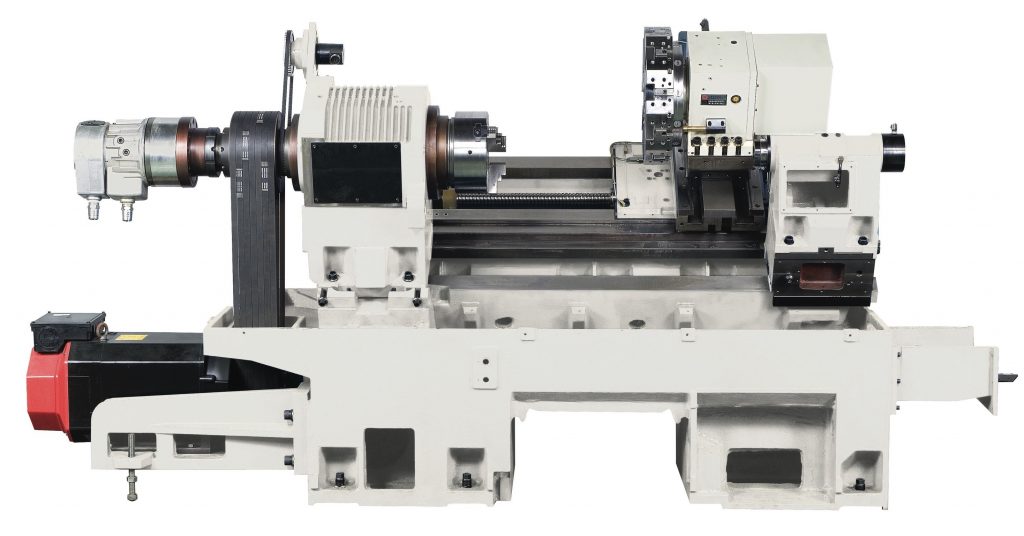

FT Series Horizontal Turning Centers

- Exceptional Rigidity – Highly Rigid Structural Frame Design

- Highly Productive – High Performing, Powerful Machining Center

- Decidedly Efficient – FANUC Advanced CNC Controllers

- Remarkably Cost Effective – Safe & Convenient

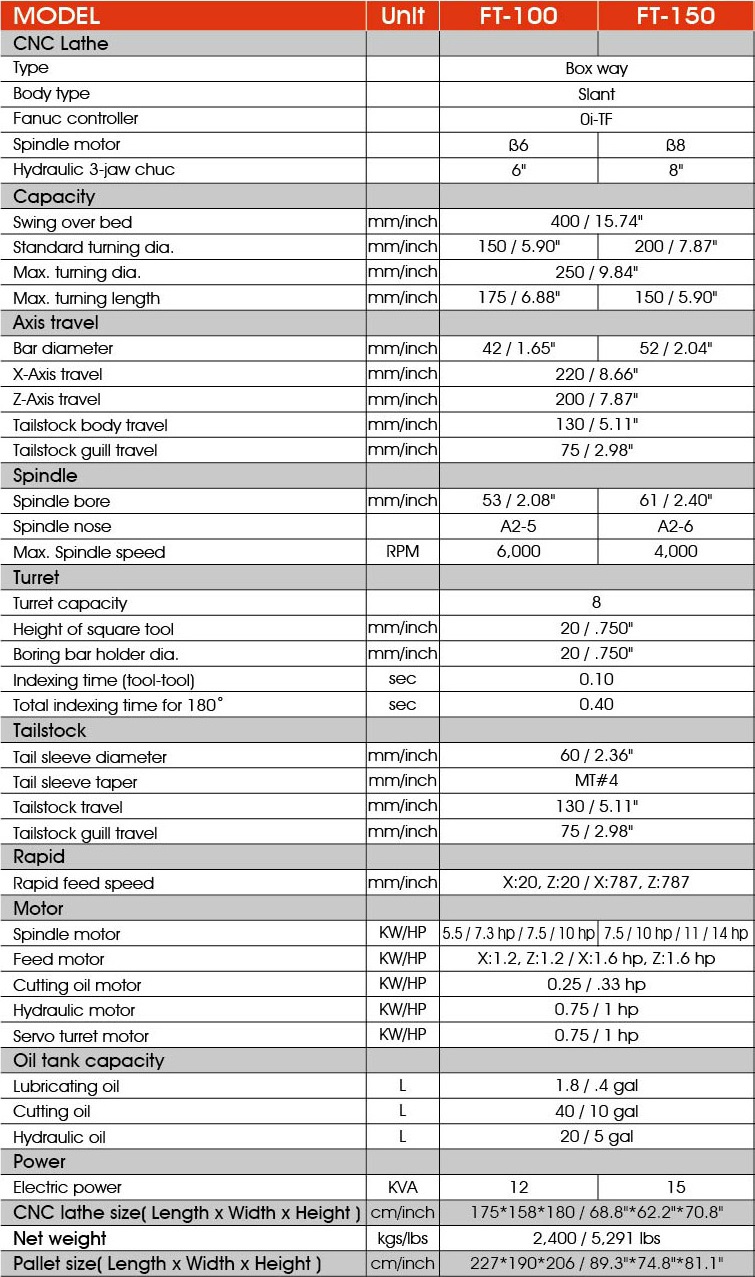

FT-100

Standard Accessories:

- 6″ Diameter with thru hole power chuck

- Spindle Bore: 53mm (2″). Draw Tube Bore: 42mm (1.7″)

- Hard jaw (6″): 1 set / Soft jaws (6″): 3 sets

- 10 station turret

- OD tool holder 2 (set)

- ID tool holder 3 (set)

- U-drill tool holder 2 (set)

- Standard morse taper socket: MT3 x 1pc

- ID sleeve ¼”, 5/16”, 3/8”, ½”, 5/8”, 13/16”

- U sleeve 1/2”, 5/8”, 13/16”

- Rapid feedrate for X & Z axes: 24 m/min

- Servo Turret

- Automatic lubrication system

- AC spindle motor for headstock: 0i-TF ß8i spindle motor 11kw cont. / 15kw 30 min.

- AC servo motor: 0i-TF C8iB for X axis: 1.2kw: C8i for Z axis: 1.2kw (1.6HP)

- Hydraulic system

- Work light

- Coolant tank system

- Chip conveyor (with chip bucket)

- Door interlock

- Heat exchanger

- Manual tailstock

- 3-color signal light

- Automatic power off

- Safety door

- Full enclosed splash guard

- One set of instruction manual

- Tool box with tool kits

- Ball screw pretention

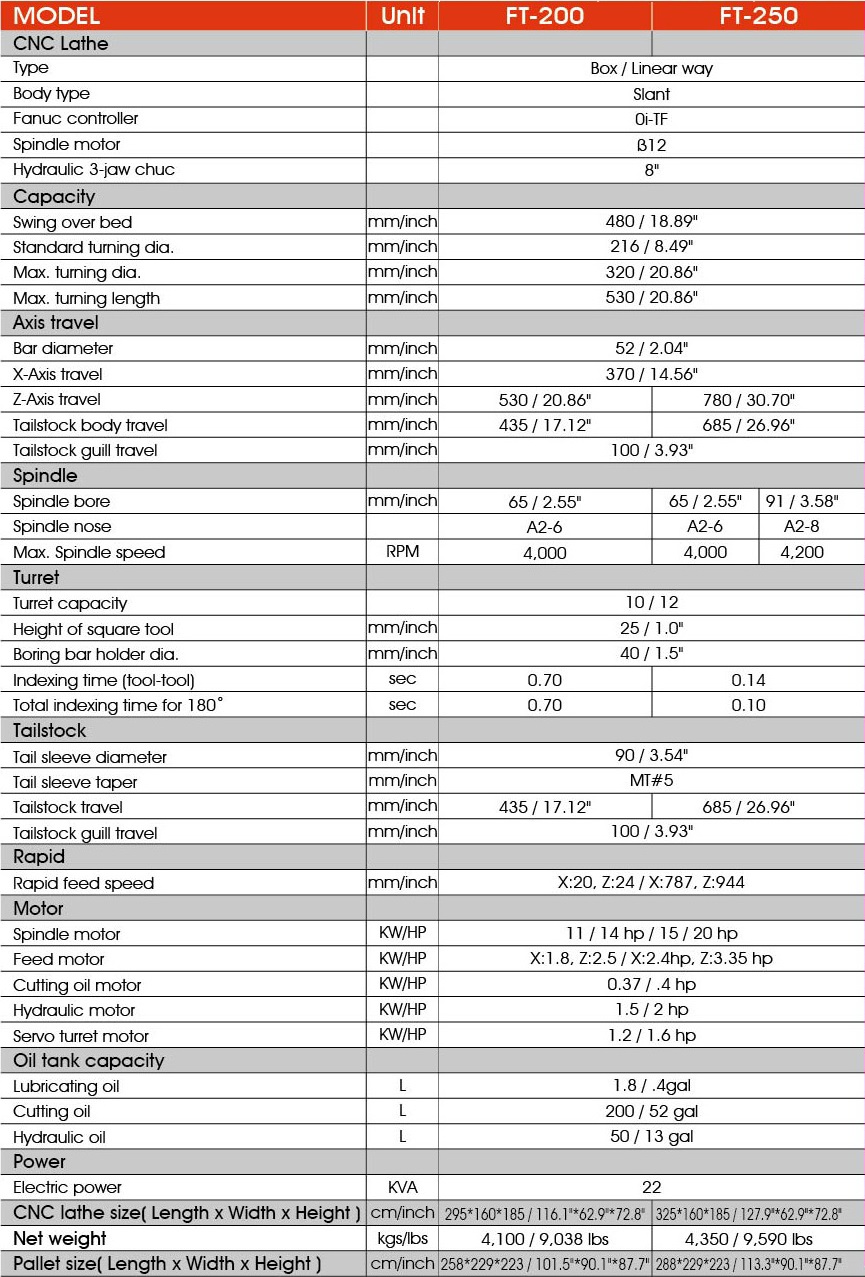

FT-200

Standard Accessories:

- Fanuc 0i-TF control

- 8″ hollow power chuck

- Spindle Bore: 65mm (2.6″). Draw Tube Bore: 52mm (2″)

- Hard jaw (8″): 1 set / Soft jaws (8″): 3 sets

- 10 station turret –

- OD tool holder 2 (set)

- ID tool holder 3 (set)

- U-drill tool holder 2 (set)

- Standard morse taper socket: MT3 x 1 pc

- ID sleeve ¼”, 5/16”, 3/8”, ½”, 5/8”, 13/16”, 1”

- U sleeve 5/8”, 13/16”, 1”, 1-1/4”

- Automatic lubrication system

- AC spindle motor for headstock: 0i-TF ß8i spindle motor 11kw cont. / 15kw 30 min. (15 / 20 HP)

- AC servo motor: 0i-TF C8iB for X axis: 1.2kw: C8i for Z axis: 1.2kw (1.6HP)

- Box Way Construction

- Rapid feedrate for X & Z axes: 20 & 24 m/min ( 787 & 944 in/min )

- Hydraulic system

- Work light

- Coolant tank system

- Chip conveyor (with chip bucket)

- Door interlock

- Quill movement adjustable by limit switch

- Heat exchanger

- Programmable tailstock

- Full enclosed splash guard

- One set of instruction manual

- Tool box with tool kits

- Automatic Power off

- Ball screw pretention

- Pallet size (L x W x H) 258*229*223mm (101.5″ x 90.1″ x 87.7″)

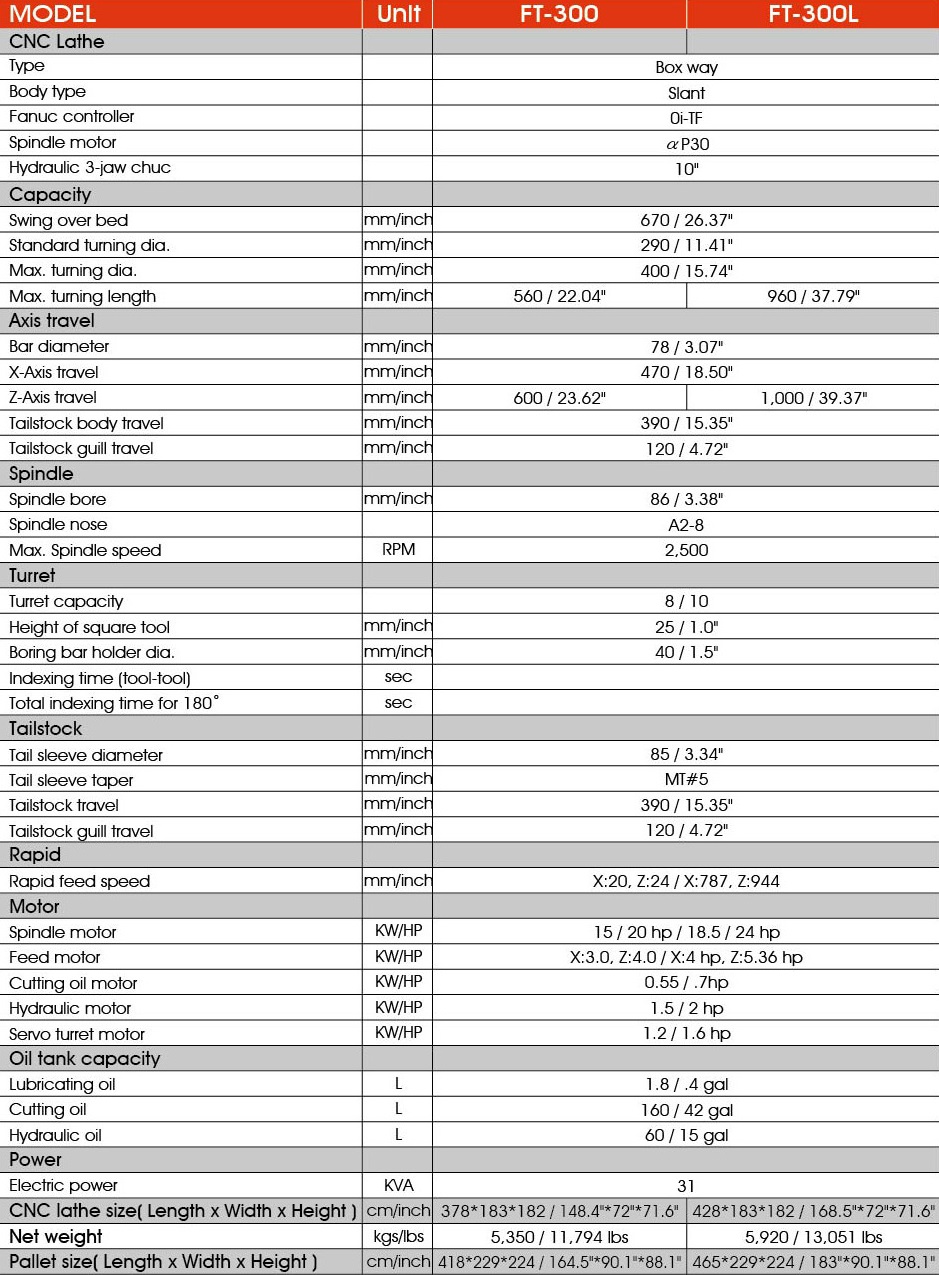

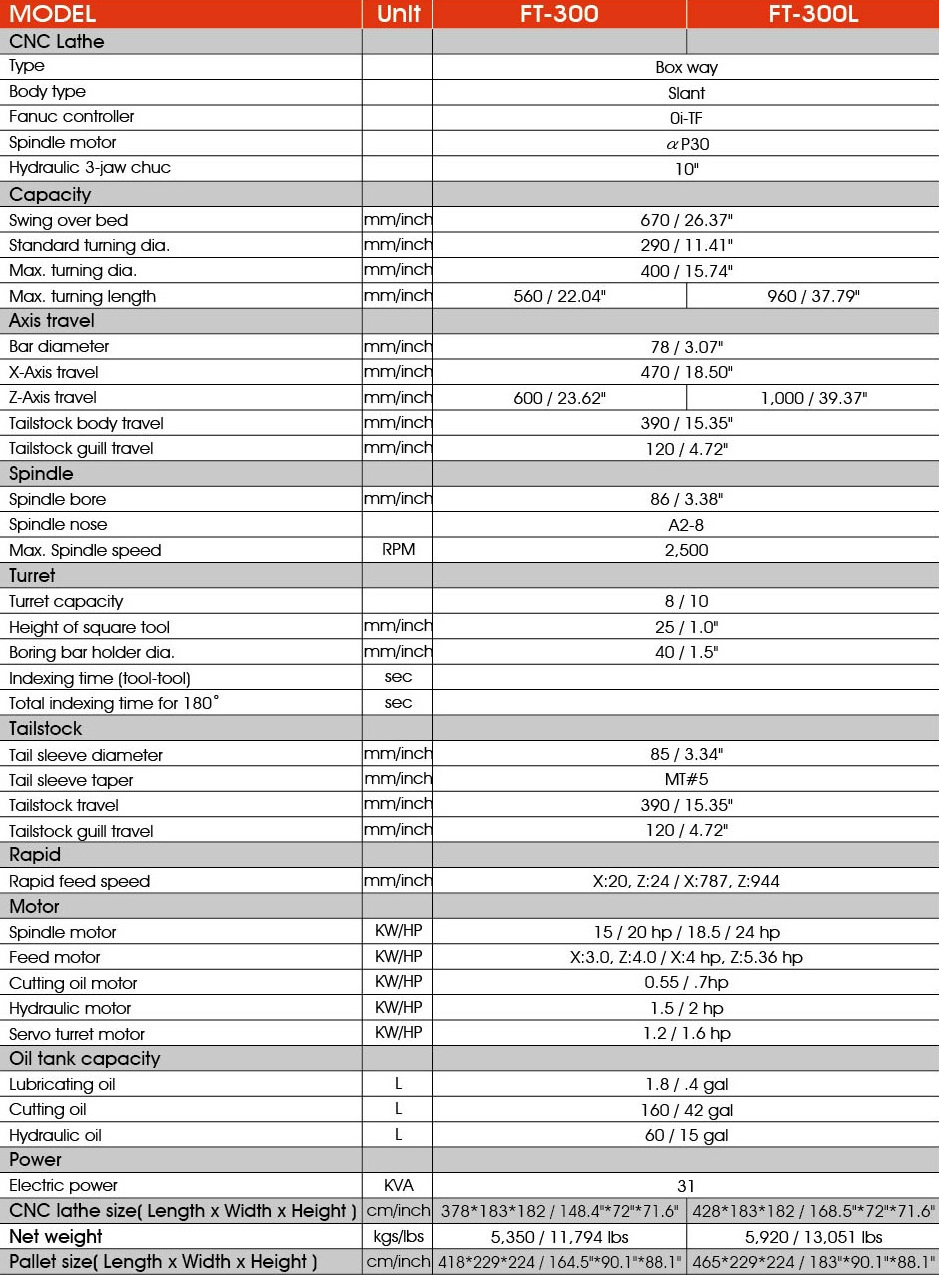

FT-300

Standard Accessories:

- Fanuc 0i-TF control

- 10″ thru hole power chuck

- Hard jaw (10″): 1 set / Soft jaws (10″): 3 sets

- 8 station turret

- OD tool holder 2 (set)

- ID tool holder 3 (set)

- U-drill tool holder 2 (set)

- Standard morse taper socket: MT3 x 1 pc

- ID sleeve 5/16”,3/8”,1/2”,5/8”,13/16”,1”,1-1/4”

- U sleeve 13/16”,1”,1-1/4”

- Hydraulic system

- Automatic lubrication system

- Work light

- Coolant tank system

- Chip conveyor (with tank)

- Door interlock

- Heat exchanger

- Programmable tailstock

- Full enclosed splash guard

- One set of instruction manual

- Tool box with tool kits

- Ball screw pretention

FT-300L

Standard Accessories:

- Fanuc 0i-TF control

- 10″ thru hole power chuck

- Hard jaw (10″): 1 set / Soft jaws (10″): 3 sets

- 10 station turret

- OD tool holder 2 (set)

- ID tool holder 3 (set)

- U-drill tool holder 2 (set)

- Standard morse taper socket: MT3 x 1 pc

- ID sleeve 5/16”,3/8”,1/2”,5/8”,13/16”,1”,1-1/4”

- U sleeve 13/16”,1”,1-1/4”

- Hydraulic system

- Automatic lubrication system

- Work light

- Coolant tank system

- Chip conveyor (with tank)

- Door interlock

- Heat exchanger

- Programmable tailstock

- Full enclosed splash guard

- One set of instruction manual

- Tool box with tool kits

- Ball screw pretention

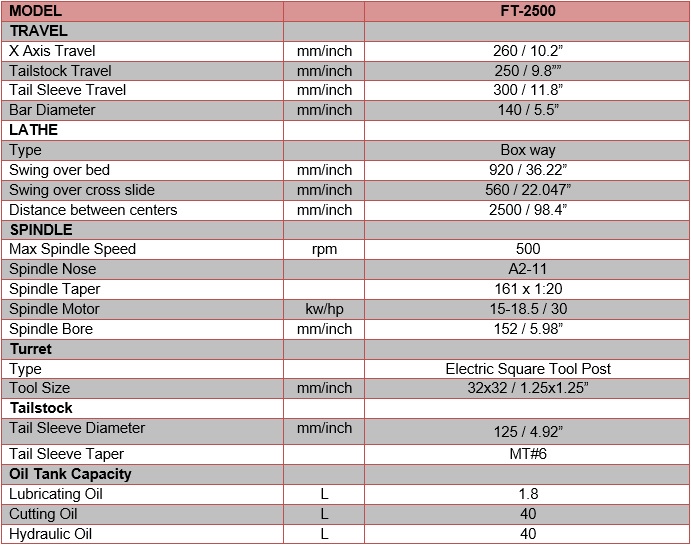

FT-2500

Standard Accessories:

- Fanuc 0iTF Control

- 20″ Diameter 4-Jaw chuck

- Hard jaw (12″): 1 set

- 8 station turret

- OD tool holder 2 (set)

- ID tool holder 3 (set)

- U-drill tool holder 2 (set)

- Tail Sleeve: MT6 x 1pc

- ID sleeve 5/8”, 13/16”, 1”

- U sleeve 13/16”, 1”

- Automatic lubrication system

- Hydraulic system

- Work light

- Coolant tank system

- Door interlock

- Heat exchanger

- Steady Rest

- 3-color signal light

- Fully enclosed splash guard

- One set of instruction manual

- Tool box with tool kits

- Ball screw pretention