DoALL Sawing Products

Circular Saws

Metal-cutting cold saws offer the ideal solution for companies looking to achieve increased cutting accuracy and performance paired with maximum safety.

At DoALL Sawing Products, we’ve spent over 90 years creating sawing machines, coolants and blades for companies across all industries and continue to be the only manufacturers that do so worldwide.

Industrial Circular Saws

Industrial Circular Cold saw machines are motor-driven circular saws with toothed cutting discs designed to cut both ferrous and non-ferrous materials, such as wood, aluminum, plastic, polystyrene and insulation. Their saw blades comprise high-speed steel or tungsten carbide and are ideal for cutting short lengths and small diameters.

DoALL provides its customers with cutting-edge industrial circular saws that set the standard for performance and dependability. Our industrial cold saws offer complete automation to deliver the most precise cuts for increased time and money savings.

We carry three circular saw solutions, including:

- SC-100A Circular Saw: This 15 horsepower (HP) cold saw reduces operator fatigue and increases user safety with automatic bar loading capabilities. With the SC-100A, you can produce the highest-quality parts with minimal effort.

- SC-150A Circular Saw: Our 25 HP automatic circular saw features a heavy-duty construction and fully digital controls to generate higher cutting rates, better surface finish, optimal accuracy and increased blade life.

- SC-75A Circular Saw: The SC-75A metal-cutting cold saw provides complete automaton with CNC controls, economic capacity, a 15 HP motor and compact design.

Industrial Applications of Metal-Cutting Cold Saws

Due to their reliable performance and versatile operation, dual-blade circular saws are used across many diverse industries and applications. These tools make powerful additions to practically any machining or fabrication shop. Their accurate part lengths and milled milter edges are ideal for manufacturing products like window and door frames. Because industrial circular saws are fully automated and therefore produce repeatable results, they’re often used in robotic welding.

Other common applications of cold saw machines include:

- Tubing and pipes.

- Sign manufacturing.

- Window frames and extensions.

- Parting operations.

- Metal fabrication.

Advantages of Dual-Blade Circular Saws

If you’re on the fence about whether to invest in a metal-cutting cold saw, consider all the advantages of these industrial tools:

- Safety: Circular saws generate fewer sparks, dust and heat than traditional saws, minimizing fire hazards in the shop.

- Performance: Due to their toothed blades, cold saws deliver clean and accurate cuts with minimal burr production and reduced discoloration, making them highly dependable for straight and angled cuts alike.

- Cost-efficiency: Though circular blades sometimes have higher initial costs, you can resharpen and reuse them dozens of times, resulting in significant long-term savings.

- Versatility: You can use dual-blade circular saws to cut materials of all shapes, such as tubes, extrusions and rods. These saws are also available in many blade configurations.

Production Band Saws

Get standard features that exceed the industry standard with the Continental Series™ metal cutting band saws by DoALL. These tools provide cutting-edge performance at a leading-edge price.

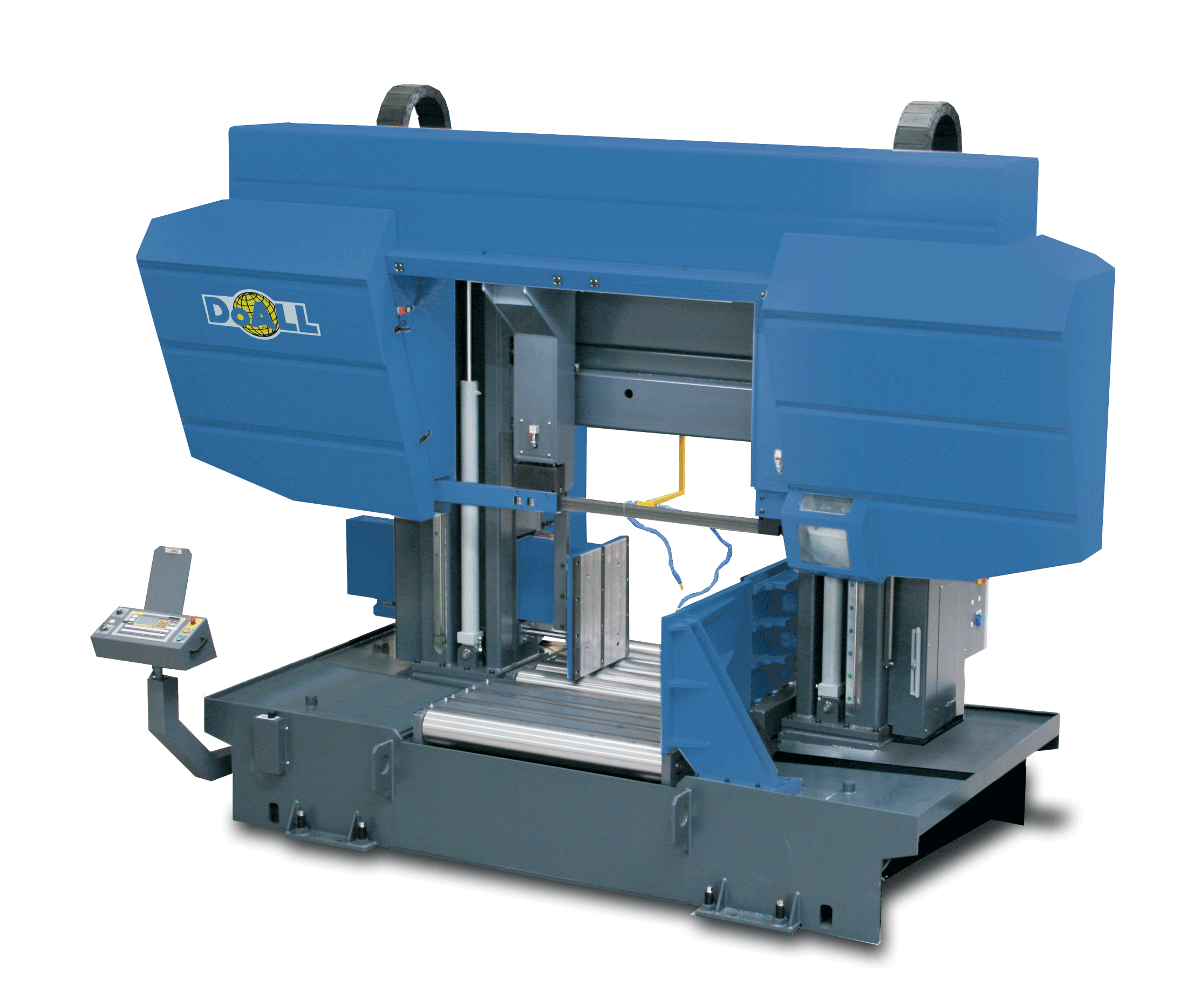

DoALL Hercules™ Dual-Column Horizontal saws are ideal for high production environments. Whether automatic, manual or numeric controlled, DoALL metal cutting, high production power band saws deliver the cutting rates and accuracy you need to keep your sawing operation running smoothly. If you’re looking for the best overall value in high production horizontal band sawing, check out DoALL — the first name in sawing for over 90 years.

Our Horizontal Double Column Miter Saws

Horizontal band saws have a long, toothed blade that swings an arc through objects positioned on a fixed cutting plane to create repeatable fixed-angle cuts. These dual-column saws are excellent for generating straight cuts with maximum precision on both wood and metal. They’re typically made from cast iron, aluminum or steel alloys.

In our inventory, you’ll find a vast array of dual-column band saws that are durable, safe and efficient, helping you produce the highest-quality cuts. We carry industrial horizontal band saws of all types, including:

- Dual-column enclosed CNC band saws.

- Dual-column semi-automatic band saws.

- Dual-column table band saws.

- Production band saws.

- Semi-automatic band saws.

- Dual-column ball screw band saws.

Applications of Dual-Column Band Saws

Horizontal double-column miter saws are widely used across various industries, such as the automotive, electrical, woodworking and electronic fields. You can most commonly find them in large-scale manufacturing companies, metal fabrication stores and industrial workshops.

With a dual-column horizontal band saw in your facility, you can accomplish any of the following applications and more:

- Cut large workpieces

- Perform high-volume cuts

- Cut tough materials

- Cutt metal stocks

- Deliver high-precision cuts

Benefits of Horizontal Band Saws

DoALL industrial horizontal band saws bring the performance, accuracy and efficiency necessary for every industrial facility. These tools offer countless operational benefits and advanced capabilities that will serve you for years to come.

Some of the many advantages of using dual-column band saws include:

- Quiet operation: Horizontal saws exhibit much quieter operation than other power tools.

- Versatility: With horizontal saws, you can work with a wide range of materials, such as wood, metal and plastics.

- Zero vibrations: Industrial horizontal band saws function without producing vibrations.

- Reduced waste: When you use our band saws, you can expect minimum wastage, saving you money.

- Performance: Horizontal saws exhibit a high cutting rate and provide exceptional squareness.

- Long blade life: Our horizontal band saws have a longer blade lifespan than other types of saws, enabling you to save on replacement blades.

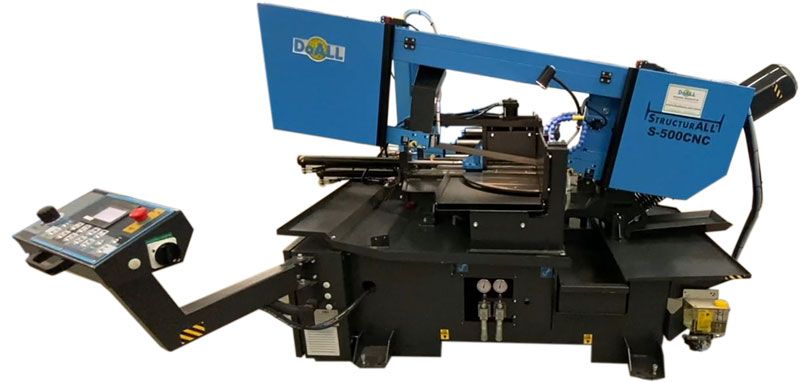

Fabrication Mitering Saws

Miter saws are essential tools for making precise angle or bevel cuts in material. They are standard tools in the woodworking and metalworking industries, as contractors and manufacturers use them for a wide variety of applications. High-production fabricators depend on miter band saws to meet their most demanding production requirements.

At DoALL, we offer an entire line of miter band saws to cover all of your cutting needs.

What Is a Miter Band Saw?

If you find yourself making frequent saw cuts at angles, a miter band saw is a great addition to your equipment list. Compound miter saws can improve your versatility and efficiency by performing angle and bevel cuts on a single pass. In addition to bevels and angles, miter band saws can complete straight crosscuts, making them one of the most versatile types of saws available.

Miter bandsaws break down into several subcategories, including scissor-style, horizontal double-column and vertical tilt-frame saws.

Miter Band Saws for Sale by DoALL Sawing Products

DoALL miter band saws set the industry’s highest efficiency, precision and durability standards. We offer an extensive selection of miter saws using work tables that tilt and swivel heads and frames. We design each model with a specific range of power and speed in mind.

Our product offerings comprise:

- Structural band saws

- Dual-column, dual-miter band saws

- Dual-column, semi-automatic band saws

- Dual-miter, manual band saws

- Dual-miter, semi-automatic band saws

- Automatic CNC swivel band saws

- Miter CNC band saws

Miter Band Saw Machine Applications

You can find our miter band saws in a broad range of facilities handling numerous applications like metal fabrication, tool and die making, manufacturing and more. We build saws that are perfect for any capacity, whether you’re cutting materials in small quantities or large production runs. Many of our standard miter saws can pair with additional pneumatic attachments to enhance their performance even more.

Some examples of relevant cutting applications include:

- Cutting large workpieces

- Cutting angles and bevels in wood products

- Performing high-volume fabrication

- Cutting rigid, heavy-duty materials

- Producing metal stock parts

- Delivering high-accuracy cuts

Benefits of Miter Band Saws

DoALL miter saws deliver the durability, efficiency and precision you need for your application, regardless of your company’s size or production scale. With their range of versatility, these saws will deliver endless benefits for many years down the road.

Here are some of the capabilities you’ll experience when you purchase our saws:

- Versatility: Miter saws can cut all types of materials in multiple ways.

- Performance: We offer miter band saws with rapid cutting speeds, high visibility and increased cutting depths to meet your production demands.

- Safety: Our saws come with features to help keep workpieces secure, minimizing the risk of injury.

- Precision: Our miter band saws feature the highest-quality blades, giving operators complete control over the cutting process.

- Less product waste: Improved accuracy in cutting translates to less product spoilage, meaning more cost savings for you.

Other advantages of purchasing a miter band saw from DoALL are our:

- Training and installation services

- ServiceALL® Preventative Maintenance Programs

- Comprehensive Warranties

Vertical Contour Saws

Vertical contour saws are among the most versatile cutting tools available. These saws can accommodate an extensive range of materials, from aluminum to steel to plastic to wood. These machines are essential for operations that cut various substrates across multiple applications.

At DoALL Sawing Products, we offer an extensive selection of vertical contour band saws to handle all of your cutting requirements.

What Is a Vertical Contour Band Saw?

Vertical contour saws are the most popular band saw across the entire industrial sector thanks to their ability to perform a wide range of tasks. Most vertical band saws use wheels that rotate on the same plane to drive the blade. The structure of the saw keeps the blade moving in the same plane as the workpiece moves into it.

Vertical band saws perform intricate contour cuts with controlled speeds and straight crosscuts at higher feed rates.

Types of Vertical Contour Band Saws We Offer

Whether you need a general-purpose upright saw at your trade school or a heavy-duty metal cutting saw for your fabrication shop, we have a perfect size and power option for your requirements. Many facilities prefer our versatile saws because they minimize the number of cutting tools they need. Our vertical band saw offerings include:

- Diamond saws

- Vertical contour band saws

- High-speed contour band saws

Vertical Contour Band Saw Applications

Vertical contour saws are present in almost any facility that needs a single cutting solution for a broad range of materials, like machine shops, maintenance departments, trade schools, tool and die shops, and more. With the ability to make linear and contour cuts, few cutting tools possess a vertical saw’s versatility. Most of our saws can easily handle multiple-piece plastic and fibrous material cutting.

Our heavy-duty models can cover all the production demands of heavy sheet metal and tough tool steel.

The following represent a few common applications:

- Multiple-piece cutting

- High-precision manufacturing

- Crosscutting

- Friction Cutting

- Contour cutting

- Metal stock fabrication

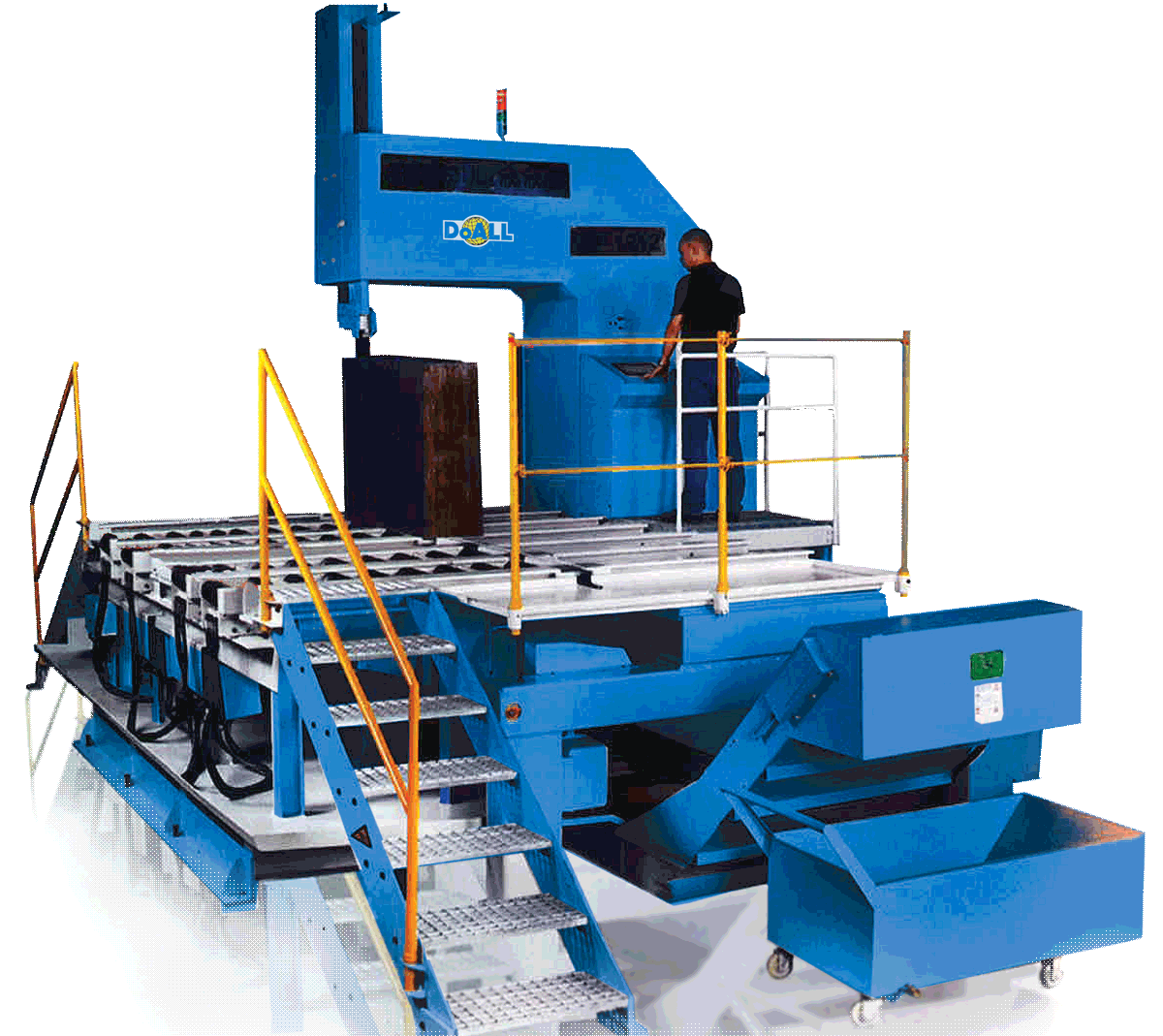

Specialty Saws

Depending on your specific application, you may need a cutting tool with a special or unique function to optimize your operation’s efficiency. At DoALL Sawing Products, our machine offerings go well beyond basic, upright band saws. We furnish industrial specialty saws to perform tasks that very few standard machines can handle.

Types of Specialty Band Saw Machines We Offer

Different sawing applications sometimes require a specific tool to get the job done right. While an upright contour saw can handle almost any task you throw at it, you may occasionally need a special saw designed to cover a particular requirement, like cutting large blocks or highly fragile material. Regardless of your cutting need, DoALL has a solution that can benefit your company’s bottom line.

Examples of our specialty saws include:

- Diamond saws: Diamonds saws get their name from the types of blades they use. The hard diamond grit edge provides precise cutting when working with quartz, glass, silicon and other abrasive composites. We offer our diamond saws in various designs and sizes to accommodate a broad range of applications.

- Vertical plate saws: We offer vertical plate saws in three capacities, all designed to cut large solid plates or blocks of material. Hydraulic blade guides, roller lift tables and chip conveyors allow for quiet and efficient cutting of the heaviest materials. Drive motors are available in 10- or 15-horsepower configurations.

- The DoALL Zephyr® vertical contour band saw: Our Zephyr vertical contour saw is unique because of its ability to cut up to 30 times faster than many conventional band saws. Its 15-horsepower AC inverter band drive can provide enough power to cut through the toughest materials, like Titanium and Inconel®. This saw is among the most dependable, versatile and durable machines on the market.

Industrial Specialty Saw Applications

Rather than making do with a saw not designed for a specific task, purchasing a specialty saw for your business might be a smart move, especially if you know you’ll be doing the same job repeatedly over an extended period. Here are a few of the unique tasks our specialty saws can handle:

- Cutting heavy grades of steel

- Beam and pipe splitting

- Cutting brittle materials, like quartz, silicon and glass

- High-speed fabrication beyond the industry standard

- Cutting large sheets or blocks too large for standard band saws

Tube Cutting Saws

Although many general-purpose vertical and horizontal band saws can handle the task of cutting tubes, a tube-cutting saw could be a beneficial addition to your operation, especially if it’s a job you perform with high frequency. Many tube cutting saw machines use special blades set to specific angles to optimize the process. At DoALL, we offer several models of tube cutting machines to meet the unique needs of your operation.

Stainless Steel and Metal Tube Cutting Saws

DoALL has the perfect tube cutting saw for your application, whether you need a high-speed machine to cut small-diameter plastic tubes or a super-duty saw to handle heavier metals. All our saws meet the highest durability, dependability, accuracy and efficiency standards.

Specific models of dual-column, tube-cutting machines we offer include:

- TDC-400CNC Tube Band Saw: Our TDC-400CNC band saw is a high-speed, hydraulically controlled saw with various speed options. The design features a 7-degree blade slope to the cutting table, enabling a higher-quality tube cut. This machine also contains an automated feed system to ensure greater cutting accuracy.

- TDC-600CNC Tube Band Saw: The TDC-600CNC saw is a heavier-duty version of the TDC-400CNC with an increased machine capacity, enabling it to cut tubes up to 24 inches in diameter. This machine can cut some of the heaviest metals without sacrificing valuable production time. An included chain chip conveyor enhances the production process even more.

- TDC-600SA Tube Band Saw: The TDC-600SA band saw features three separate pulleys and a blade set with a 10-degree cantilever to allow high-precision cutting. The feed system contains vises that automatically clamp the tube and guide it through the blade, ensuring the highest cutting accuracy. This saw is perfect for cutting an extensive range of pipes and tubes, including tool steel and other heavy metals.

Tube Saw Cutting Applications

Our tube cutting saws cover a wide range of applications across various industries. By using a saw specifically designed for tube fabrication and cutting, you can streamline your operation’s efficiency, saving you both time and money over the long run. You’ll often find these saws in industries such as:

- Metal center processing

- Gas and oil contracting

- Plastic tube fabrication

- HVAC parts manufacturing

- Public facilities work

- Metal tube cutting

Benefits of Tube Cutting Saws

By purchasing a saw designed specifically for your operation, you’ll experience many benefits, particularly if you’re cutting tubes at high frequencies. Some advantages of owning a tube cutting saw machine include:

- Greater cutting speeds: Auto-indexing and nesting allow you to load multiple tubes and pipes and cut at increased rates.

- More precise cuts: Sloped blades ensure optimal performance and more accurate cuts.

- Increased feed accuracy: The hydraulic clamping and guide system allows precise control throughout the cutting process.

- Enhanced safety: Automated feed and take-off options translate to higher safety levels for your machine operators.