KENT CNC

Vertical Machining Centers

Increase your profitability with Kent CNC’s Vertical Machining Centers—long-lasting units that deliver a precision-grade finish at high speeds. Our Vertical Machining Center product portfolio offers a wide selection of powerful, rigid machines including compact models, standard #40 and # 50 taper models, models with traveling column or double column designs, and compact 5-axis machining centers with rotary table style or trunnion style designs. With over 22,000 machine tools sold worldwide since 1979, CNC vertical milling centers being one of the biggest portions of it, Kent CNC VMCs are proven to increase productivity, delivering reliable and profitable performance.

Linear Way 3-Axis VMC

Heavy Duty Box Way VMC

Traveling Column VMC

Horizontal Turning Centers

Our broad range of horizontal turning centers offers a variety of bore sizes, bed lengths, and optional features. From basic 2-axis turning to sub-spindle and live turret turning models, there is a Kent CNC turning center to meet your needs.

We offer the following:

Gang Style Lathe

2-Axis

Mill-Turn

Sub-spindle

Large Bore Turning Centers

Heavy Duty Boring Turning Centers

5 Bed Way Heavy Duty Extra Long Turning Centers

5-Axis Milling Turning Center Series

Double Turret Turning Centers

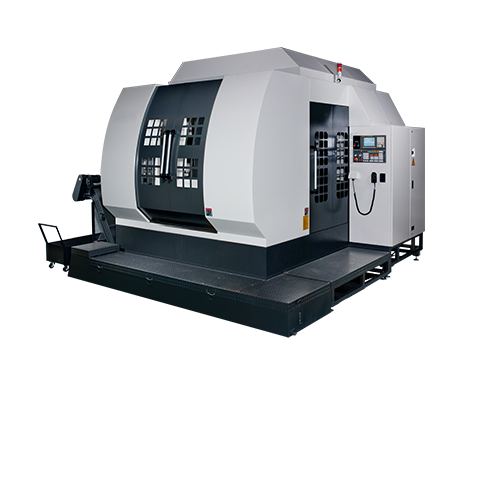

Horizontal Machining Centers

Our Kent CNC Horizontal Machining Centers are constructed with rigid structural parts combined with a “V” shaped rib reinforcement that ensures stability. Our machines will assist you in becoming more diverse and flexible by dramatically decreasing your lead-times while reducing production costs. Our HMC’s cut down operating costs by decreasing the amount of damaged parts produced, increasing repeatability and by accomplishing the most precise cuts with the assistance of rapid tool change out.

Programmed with advanced finite element analysis software technology, Kent CNC Horizontal Machining Centers are designed to meet your highest demands, whether it’s manufacturing high-quality cast iron or automating your production, setting you apart from the competition. With our CNC machines, any demand is attainable; our machines utilize less resources and raw materials and are extremely energy efficient. You can program your HMC to run long periods of time, including overnight and weekends, without risks of downtime, machine malfunction or part change out, making our machines the most self-sufficient in the market.

We offer the following:

HMC with APC

HMC without APC

HMC with Vertical Spindle

Vertical Turning Centers

Kent CNC offers a compact and a heavy duty line of vertical turning centers. Vertical turning centers or vertical turning lathes let gravity reinforce the workpiece’s stability. The weight of the workpiece goes straight down into the machine’s foundation to minimize inaccuracies. The vertical turning orientation reduces clamping force needed for workpiece holding. This also allows for greater workpiece weight capacity. In addition, vertical turning lathes typically have smaller footprints than their horizontal turning center counterparts.

We offer the following:

Compact Series

Large Heavy Duty Series