Heidenhain – Acu-Rite

Mill and lathe controls

We offer the following:

MILLPWR G2

TURNPWR

Digital readouts

Encoders

Our standard bearing readouts and controls are even more effective when they’re paired with the right equipment. As part of the HEIDENHAIN Family of Brands, we offer world-class encoders and touch probes. We also go to great lengths to make it easy to install our equipment whether you’re retrofitting an old machine or adding on.

We offer the following:

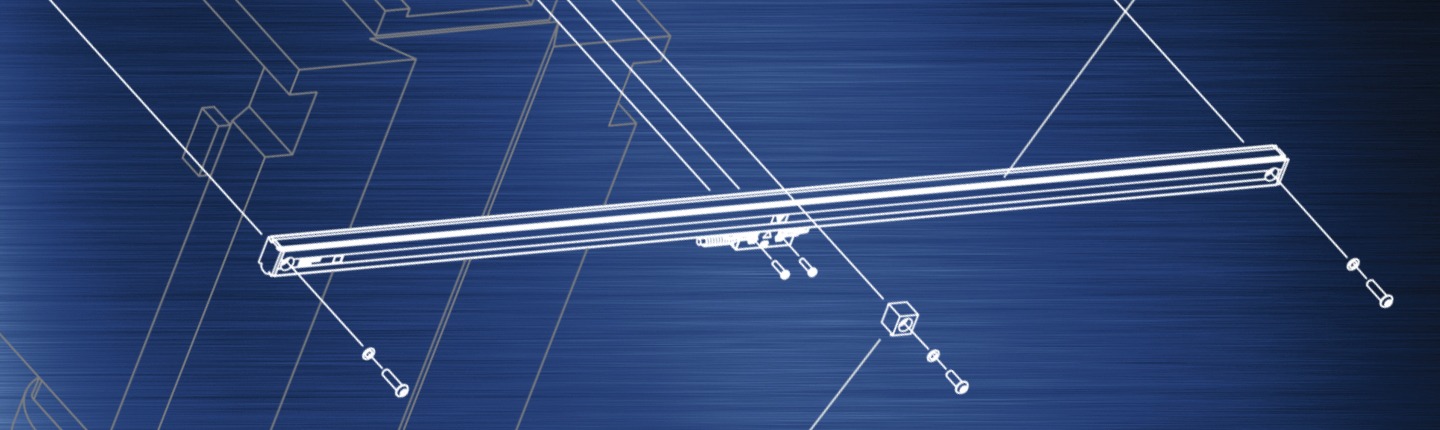

SENC 50

SENC 150

LMF 9310

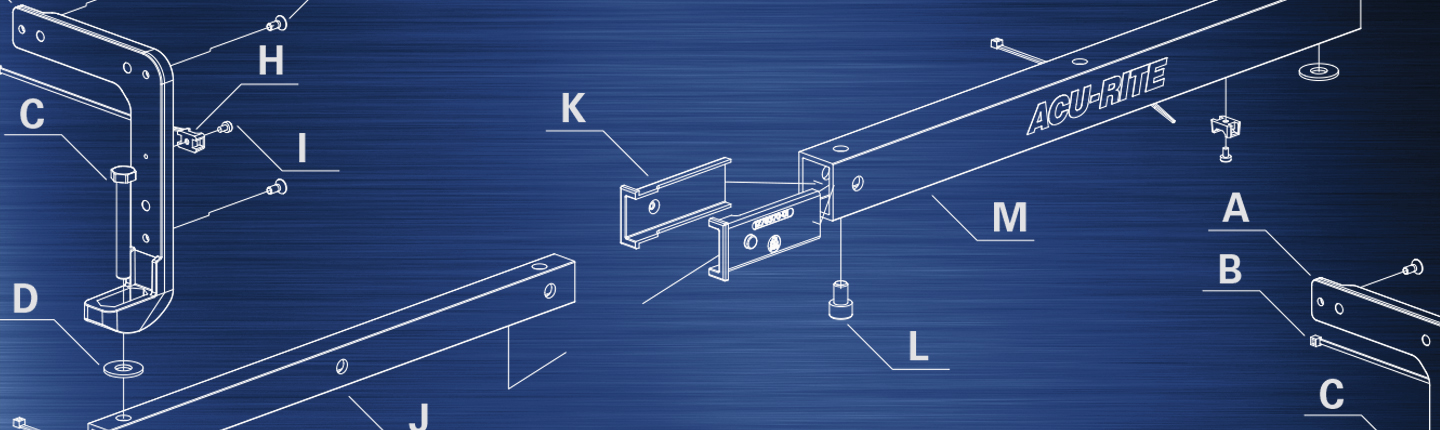

Mounting brackets and edge finders

Scale and readout mounting brackets are specifically designed for applications and machine brand. Crucial to operational performance and accuracy, these make proper installation simple without any modification. Find brackets specifically for milling, turning and grinding applications and dozens of machine brands and sizes.

Our 3-D electronic Edge Finder is an ideal tool for any machinist or operator responsible for efficient, accurate work.

We offer the following:

Scale mounting brackets

Readout mounting brackets

Edge finder